Material: Ss, Q235, Q345R , SA516GR70 , SS304 SS316L, etc

Diameter: 89 mm - 10000 mm

Thickness: 2-100mm

Technology: Hot Pressing, Cold Pressing

Surface Treatment: Sand Blasting, Pickling, Mirror Polished,etc

Test: UT,RT,MT,PT,ET

Standard Ellipsoidal Head For Vessel Dished Head

Item : | Standard Ellipsoidal Head For Vessel Dished Head |

Diameter: | 89mm--10000mm |

Thickness: | 2mm--100mm |

Reduction Ratio: | about 10% |

Material: | Carbon stee(A3,20#,Q235,Q345B,16Mn), Alloy steel(15Mo3 15CrMoV 35CrMoV 45CrMo), |

Stainless steel (304,321,304L,316,316L), etc | |

According to customers requirement (If you can use Chinese material is the best.) | |

Technology: | Hot pressing, cold pressing |

Surface Treatment: | Sand Blasting, Transparent oil, Rust-proof oil, Galvanizing |

Test: | UT,RT,MT,PT,ET |

Applicable Standard | ANSI, ASME ,MSS, API, DIN, JIS, BS. AWWA and GB |

Certificate: | ISO9001 ,ISO14001,OHSAS18001 |

Applications: | Such as: oil, chemical industry, water conservancy, electric power, |

boiler, machinery, metallurgy, sanitary construction etc. | |

Product Character | Rustproof, good corrosion resistance, anti-wearing, good-appearance, excellent mechanical properties. |

Connection | Butt-welding |

Packaging: | Standard seaworthy export packing: Plywood Box, Plywood or Steel Pallet or as per customers requirement |

Delivery time: | According to customers requirement |

OEM,ODM | Available |

Others: | 1. Special design available according to your drawing. |

2. Anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

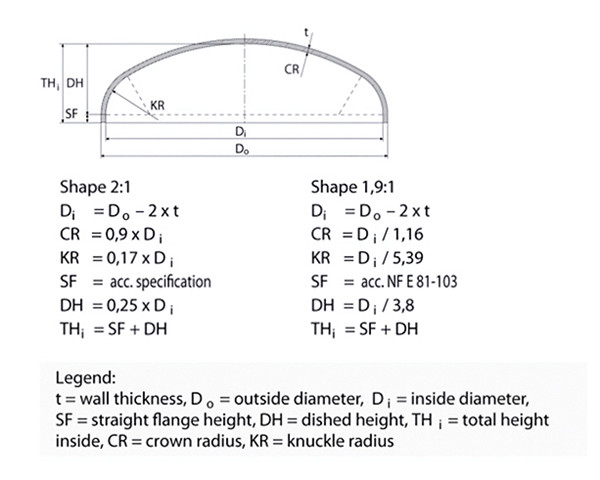

Ellipsoidal Head Specifications:

Ellipsoidal head is also called elliptical head or elliptical dish end. The shape of this ellipsoidal head is more economical, because the height of the head is just a fraction of the diameter. The elliptical dish end radius varies between the major and minor axis usually with the ratio is 2:1. The elliptical tank head is the economical solution for medium pressure tanks due to the reduced metal thickness requirement.

Processing Step: Picking steel---Cutting---Welding---Heating---Spinning---Stamping---Trimming---Defect detection---QC---Warehousing---Transporttation

.

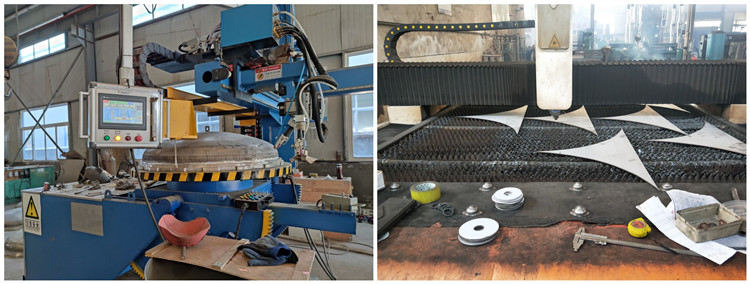

Ellipsoidal Head Pictures:

Hemispherical Head Factory Information:

Our company has more than 80 skilled workers, 11 of whom are technicians, 2 sets of fully automatic welding machines, 1 set of laser cutting machines, more than 10 sets of automatic polishing equipment, 1 set of effective elimination equipment, and 2 sets of fully automatic welding machines with various production and testing equipment. One stove, one set of X-ray equipment, one set of metal element testing equipment, multiple lifting equipment, multiple machining equipment, etc.

Workshop on Our Tank Heads

With over 15 years experience in this industry, we have cooperated with various customers from the whole world. And built an ongoing relationship with them already. Thanks to our quality control and producing team, and the support from our clients, we have won the good praise from them in various products including: hemisphere head, elliptical head, dish head, spherical head, flat head, conical head, BBQ firepit series.

Payment and Shipping Methods

As a professional manufacturer and supplier for the tank heads, we support various payment and shipping methods.

We can take PayPal for the sampling order, and bank transfer, L/C for the bulk order.

We'd like to ship out the samples via DHL, Fedex, UPS, TNT, and ship out the mass production by boat.

As well as, we accpet various price terms and policies including EXW, FOB, CIF, CNF, DDP, DDU, DAP, ect.

Frequently Asked Questions

Q1. What is your terms of packing?

A: Generally, we pack our goods by plywood pallet , steel pallet or carton box. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8. What's the information should I provide when inquiry?

A. If you have drawings, we will be entirely in accordance with production drawings. If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head, diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

Q9. What are surface treatment of the product?

A. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

Q10. How do you ensure the quality of products?

A. Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

Q11. Can you help us matching related products?

A. Our company also is surrounded by a lot of ancillary businesses, such as firepit bowls flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices.

Contact: Judy Wu

Phone: + 86 15269864663

E-mail: [email protected]

Add: Qiu Jiadian Industrial Park, Tai'an City, Shandong Province, China